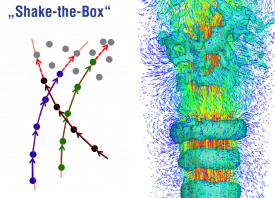

FlowMaster 4D-PTV / Shake-the-Box

Shake-the-Box is the most advanced 3D Lagrangian Particle Tracking Velocimetry (PTV) method for densely seeded flows at highest spatial resolution. Compared to the voxel-based Tomo-PIV approach Shake-the-Box is a purely particle-based technique using an Iterative Particle Reconstruction (IPR) technique in combination with an advanced 4D-PTV algorithm using the time-information for track reconstruction. Shake-the-Box achieves a higher reconstruction accuracy at much faster processing speed compared with its TR-Tomo-PIV counterpart.

Beside different DaVis software packages FlowMaster systems for TR-Tomo-PIV and Shake-the-Box are using the same hardware.

- Time-resolved PTV for 4D flow analysis at high seeding densities

- Award-winning particle reconstruction and tracking algorithm:

4th International PIV Challenge - Unsurpassed precision for velocity and acceleration of particle tracks

- Very fast processing speed

- Hardware compatible with FlowMaster TR-Tomo-PIV setups

Multi-pulse Shake-the-Box

Multi-pulse Shake-the-Box offers the possibility to yield volumetric data at highest flow velocities. Here, double-frame cameras, as commonly used in many PIV applications, are used instead of high-speed cameras. Due to the very short inter-frame timings (down to 100ns) of the double-frame cameras, optimal particle displacements can be guaranteed.

From the Multi-pulse STB method, the two different recording strategies 2-pulse STB (single-illuminated double-frame recordings) and 4-pulse STB (double-illuminated double-frame recordings) can be chosen from. Whereas 2-pulse STB is able to reconstruct highly resolved flow fields with only minimal temporal information, 4-pulse STB offers the possibility to extract all acceleration terms at the same time.

Due to its particle-based reconstruction technique, Multi-pulse STB does not only need far less memory capacities than classic Tomographic PIV methods, its processing speed is also significantly faster. This enables the use of high-resolution cameras and makes it possible to identify even the smallest flow structures in large measurement volumes.

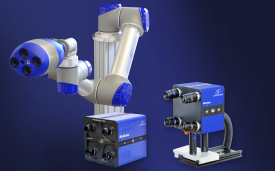

MiniShaker: compact 3D camera for volumetric flow measurements

The MiniShaker is an aligned multi-sensor system in a compact housing for quick and easy volumetric flow measurements. Integrated into LaVision’s DaVis software, Shake-the-Box (4D-PTV) as well as Tomographic PIV flow fields are readily obtained. The power supply and data transfer of the system both use USB-3 interfaces largely simplifying installation and operation.

The MiniShaker is available in three models and with adaptable lenses for diverse measurement tasks. In combination with LaVision’s cost-effective LED-Flashlight it is ideal for measurements of water applications. Mounted to a robotic arm and combined with Helium-filled Soap Bubble seeding, the flexible system is most appropriate for large-scale flow analysis of low- to mid-speed wind tunnel and convective air flow applications.

courtesy DLR Goettingen

Large Scale PIV/PTV in air

Air seeding with µm-particles is not suitable for large scale PIV/PTV experiments due to their limited scattering power. Neutrally buoyant Helium-filled Soap Bubbles (HFSB) with a diameter of 0.3 mm and a response time less than 15 µs scatter 10000x more light than µm-particles and, therefore, are suitable for large scale PIV/PTV experiments in the lower subsonic regime.

LaVision’s HFSB Seeding Generator can deliver 0.3 mm mono-sized bubbles at a production rate of 40000 bubbles per second and per nozzle and can operate simultaneously up to 60 nozzles in parallel. The typical life time of the Helium-filled soap bubbles is a few minutes. Furthermore, the increased scattering intensity allows to switch from laser to LED illumination, greatly reducing the cost of the light source.

Time-Resolved 3D Flow Field Imaging in a Wind Tunnel for Full Scale Automotive Testing

Time-resolved 3D flow fields have been successfully measured behind a serial car in a large wind tunnel at Volkswagen. The field-of-view was 2 m x 1.6 m with a light sheet thickness of 0.2 m. The air flow was seeded with 0.3 mm in diameter Helium-filled soap bubbles applying seeding rates of more than 2 million bubbles per second operating 60 seeding nozzles.

Four high-speed cameras recorded the 3D wake flow at wind speeds of 60 km/h and 120 km/h, respectively. A high-speed laser was used for illumination. LaVision’s Shake-the-Box time-resolved 3D-PTV technique was applied to calculate the time-resolved 3D flow fields.